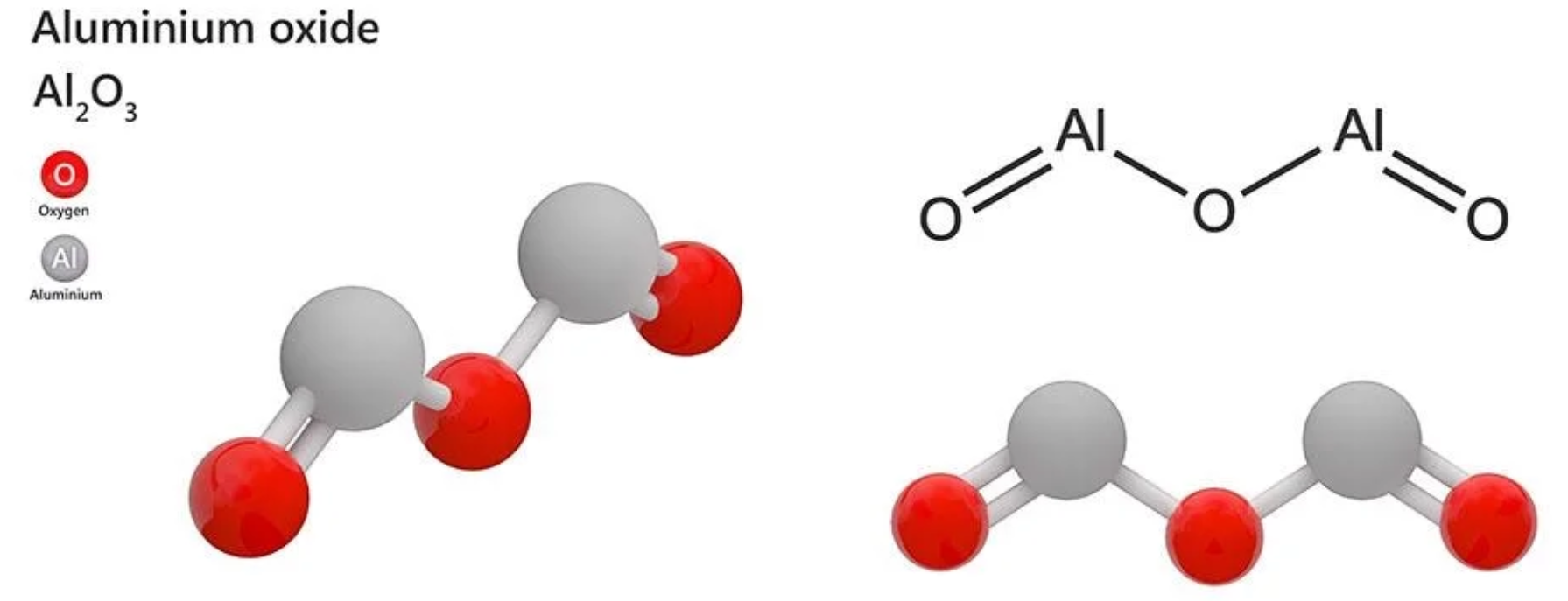

♦Alumina (Al)2O3)

Partes ceramicae praecisionis a ZhongHui Intelligent Manufacturing Group (ZHHIMG) productae ex materiis crudis ceramicis altae puritatis, alumina 92~97%, alumina 99.5%, alumina >99.9%, et pressa isostatica frigida CIP fieri possunt. Sinterizatione altae temperaturae et machinatione praecisionis, accuratio dimensionalis ± 0.001mm, levitas usque ad Ra0.1, temperatura usus usque ad 1600 gradus. Colores ceramicae varii secundum desideria emptorum fieri possunt, ut: niger, albus, fulvus, ruber obscurus, etc. Partes ceramicae praecisionis a nostra societate productae temperaturae altae, corrosioni, detritioni et insulationi resistunt, et diu in temperatura alta, vacuo et ambitu gasorum corrosivorum adhiberi possunt.

Late adhibitus in variis apparatibus productionis semiconductorum: Quadris (fulcris ceramicis), Substratis (basis), Brachiis/Pontibus (manipulatoribus), Partibus Mechanicis et Ferculis Aereis Ceramicis.

| Nomen Producti | Tubus/Pipa/Virga Quadrata Aluminae Ceramicae Altae Puritatis 99 | |||||

| Index | Unitas | 85% Al₂O₃ | 95% Al₂O₃ | 99% Al₂O₃ | 99.5% Al₂O₃ | |

| Densitas | g/cm³ | 3.3 | 3.65 | 3.8 | 3.9 | |

| Absorptio Aquae | % | <0.1 | <0.1 | 0 | 0 | |

| Temperatura Sinterizata | Celsius | 1620 | 1650 | MDCCC | MDCCC | |

| Duritia | Mohs | 7 | 9 | 9 | 9 | |

| Robur Flexionis (20℃) | MPA | ducenti | trecenti | 340 | 360 | |

| Robur Compressivum | Kilogrammo per cm² | Decem milia | 25000 | Tria milia | Tria milia | |

| Temperatura Operandi Diuturna | Celsius | 1350 | 1400 | 1600 | 1650 | |

| Temperatura Maxima Operativa | Celsius | 1450 | 1600 | MDCCC | MDCCC | |

| Resistivitas Voluminis | 20℃ | Ω. cm³ | >1013 | >1013 | >1013 | >1013 |

| 100℃ | 1012-1013 | 1012-1013 | 1012-1013 | 1012-1013 | ||

| 300℃ | >109 | >1010 | >1012 | >1012 | ||

Usus ceramicae aluminae altae puritatis:

1. Ad apparatum semiconductorum applicatum: mandrinum vacuum ceramicum, discus secans, discus purgans, mandrinum ceramicum.

2. Partes translationis laminarum: mandrinae tractationis laminarum, disci secandi laminarum, disci purgandi laminarum, poculae suctionis ad inspectionem opticam laminarum.

3. Industria ostentationis planae LED/LCD: rostrum ceramicum, discus ceramicus molendi, CLAVUS ELEVATORIUS, CLAVUS FERRIVIUS.

4. Communicatio optica, industria solaris: tubi ceramici, virgae ceramicae, radulae ceramicae pro impressione serigraphica tabularum circuituum.

5. Partes calori resistentes et electricae insulationis: fercula ceramica.

Hodie, ceramica oxidi aluminii in ceramicas altae puritatis et communes dividi potest. Series ceramicarum oxidi aluminii altae puritatis ad materiam ceramicam plus quam 99.9% Al₂O₃ continentem refertur. Propter temperaturam sinterizationis usque ad 1650-1990°C et longitudinem undae transmissionis 1 ~ 6μm, plerumque in vitrum fusum loco cruciuli platini tractatur: quod propter transmissionem lucis et resistentiam corrosionis a metallis alcalinis ut tubus natrii adhiberi potest. In industria electronica, ut materia insulans altae frequentiae pro substratis circuituum integratorum adhiberi potest. Secundum diversa contenta oxidi aluminii, series ceramica oxidi aluminii communis in ceramicas 99, ceramicas 95, ceramicas 90 et ceramicas 85 dividi potest. Interdum, ceramica cum 80% vel 75% oxidi aluminii etiam ut series ceramica oxidi aluminii communis classificatur. Inter ea, materia ceramica oxidi aluminii 99 ad producendum crucibulum temperaturae altae, tubos fornacis ignifugos, et materias speciales attritioni resistentes, ut fercula ceramica, sigilla ceramica, et laminas valvularum, adhibetur. Ceramica oxidi aluminii 95 imprimis ut pars corrosioni et attritioni resistens adhibetur. Ceramica oxidi 85 saepe quibusdam proprietatibus mixta est, ita efficaciam electricam et robur mechanicum augens. Sigilla molybdeni, niobii, tantali, et alia metallica adhiberi possunt, et quaedam ut instrumenta electrica vacui adhibentur.

| Res Qualitatis (Valor Repraesentativus) | Nomen Producti | AES-12 | AES-11 | AES-11C | AES-11F | AES-22S | AES-23 | AL-31-03 | |

| Compositione Chemica: Productum Sinterizationis Facilis, Pauco Natrio | Aqua | % | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Haha | % | 0.1 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| Fe₂O₃ | % | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | |

| SiO₂ | % | 0.03 | 0.03 | 0.03 | 0.03 | 0.02 | 0.04 | 0.04 | |

| Na₂O | % | 0.04 | 0.04 | 0.04 | 0.04 | 0.02 | 0.04 | 0.03 | |

| MgO* | % | - | 0.11 | 0.05 | 0.05 | - | - | - | |

| Al₂O₃ | % | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | |

| Diameter Particulae Mediae (MT-3300, methodus analysis laserica) | μm | 0.44 | 0.43 | 0.39 | 0.47 | 1.1 | 2.2 | 3 | |

| Magnitudo Crystalli α | μm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 ~ 1.0 | 0.3 ~ 4 | 0.3 ~ 4 | |

| Densitas Formans** | g/cm³ | 2.22 | 2.22 | 2.2 | 2.17 | 2.35 | 2.57 | 2.56 | |

| Densitas Sinterizationis** | g/cm³ | 3.88 | 3.93 | 3.94 | 3.93 | 3.88 | 3.77 | 3.22 | |

| Frequentia Contractionis Lineae Sinterizationis** | % | 17 | 17 | 18 | 18 | 15 | 12 | 7 | |

* MgO in calculo puritatis Al₂O₃ non includitur.

* Pulvis sine squamis 29.4MPa (300kg/cm²), temperatura sinterizationis est 1600°C.

AES-11 / 11C / 11F: Adde 0.05 ~ 0.1% MgO, sinterabilitas excellens est, ita ad ceramicas oxidi aluminii cum puritate plus quam 99% applicabilis est.

AES-22S: Alta densitate formationis et brevi contractionis celeritate lineae sinterizationis insignita, ad formas labentes fusionis et alia producta magnae scalae cum requisita accuratione dimensionali applicabilis est.

AES-23 / AES-31-03: Densitatem formandi, thixotropiam et viscositatem inferiorem quam AES-22S habet. Prius ad ceramicas adhibetur, posterius autem ut aquae reductor in materiis ignifugis, popularitatem adipiscens.

♦Characteres Carburis Silicii (SiC)

| Characteres Generales | Puritas principalium partium (pondus %) | 97 | |

| Color | Niger | ||

| Densitas (g/cm³) | 3.1 | ||

| Absorptio aquae (%) | 0 | ||

| Proprietates Mechanicae | Robur flexurale (MPa) | quadringenti | |

| Modulus Iuvenis (GPa) | quadringenti | ||

| Duritia Vickersiana (GPa) | 20 | ||

| Proprietates Thermicae | Temperatura maxima operandi (°C) | 1600 | |

| Coefficiens expansionis thermalis | Temperatura ~500°C | 3.9 | |

| (1/°C × 10⁻⁶) | Temperatura ~800°C | 4.3 | |

| Conductivitas thermalis (W/m × K) | 130 110 | ||

| Resistentia impetus thermalis ΔT (°C) | trecenti | ||

| Proprietates electricae | Resistivitas voluminis | XXV°C | 3 x 106 |

| 300°C | - | ||

| 500°C | - | ||

| 800°C | - | ||

| Constans dielectrica | 10GHz | - | |

| Iactura dielectrica (× 10⁻⁴) | - | ||

| Factor Q (x 10⁴) | - | ||

| Tensio disruptionis dielectricae (KV/mm) | - | ||

♦ Ceramica Nitrida Silicii

| Materia | Unitas | Si₃N₄ |

| Methodus Sinterizationis | - | Pressura Gasis Sinterizata |

| Densitas | g/cm³ | 3.22 |

| Color | - | Griseus Obscurus |

| Ratio Absorptionis Aquae | % | 0 |

| Modulus Iuvenis | GPA | 290 |

| Duritia Vickersiana | GPA | XVIII - XX |

| Robur Compressivum | MPA | MMCC |

| Vis Flexionis | MPA | DCCL |

| Conductivitas Thermalis | W/mK | 25 |

| Resistentia Ictus Thermalis | Δ (°C) | 450 - 650 |

| Temperatura Operativa Maxima | °C | 1200 |

| Resistivitas Voluminis | Ω·cm | > 10 ^ 14 |

| Constans Dielectrica | - | 8.2 |

| Robur Dielectricum | kV/mm | 16 |